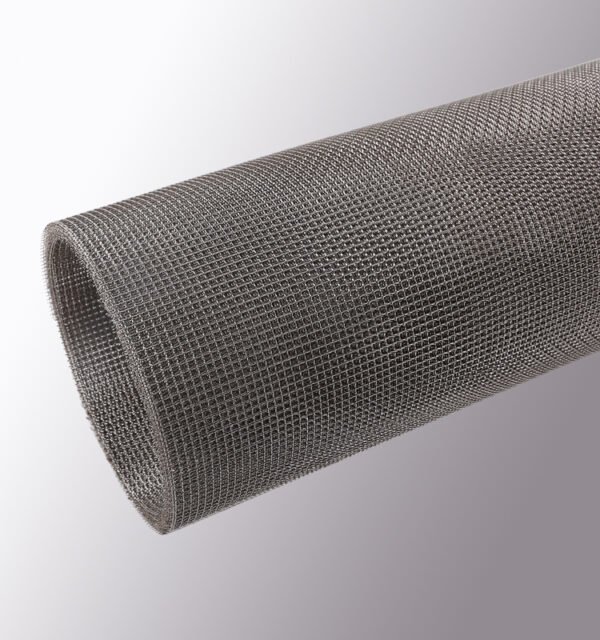

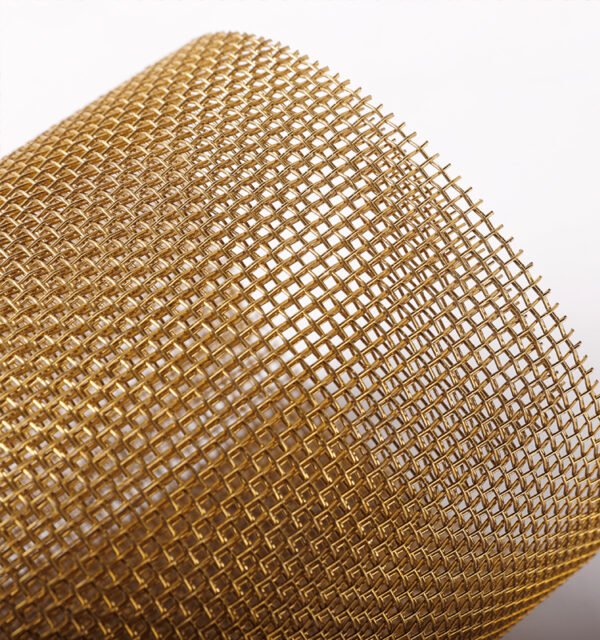

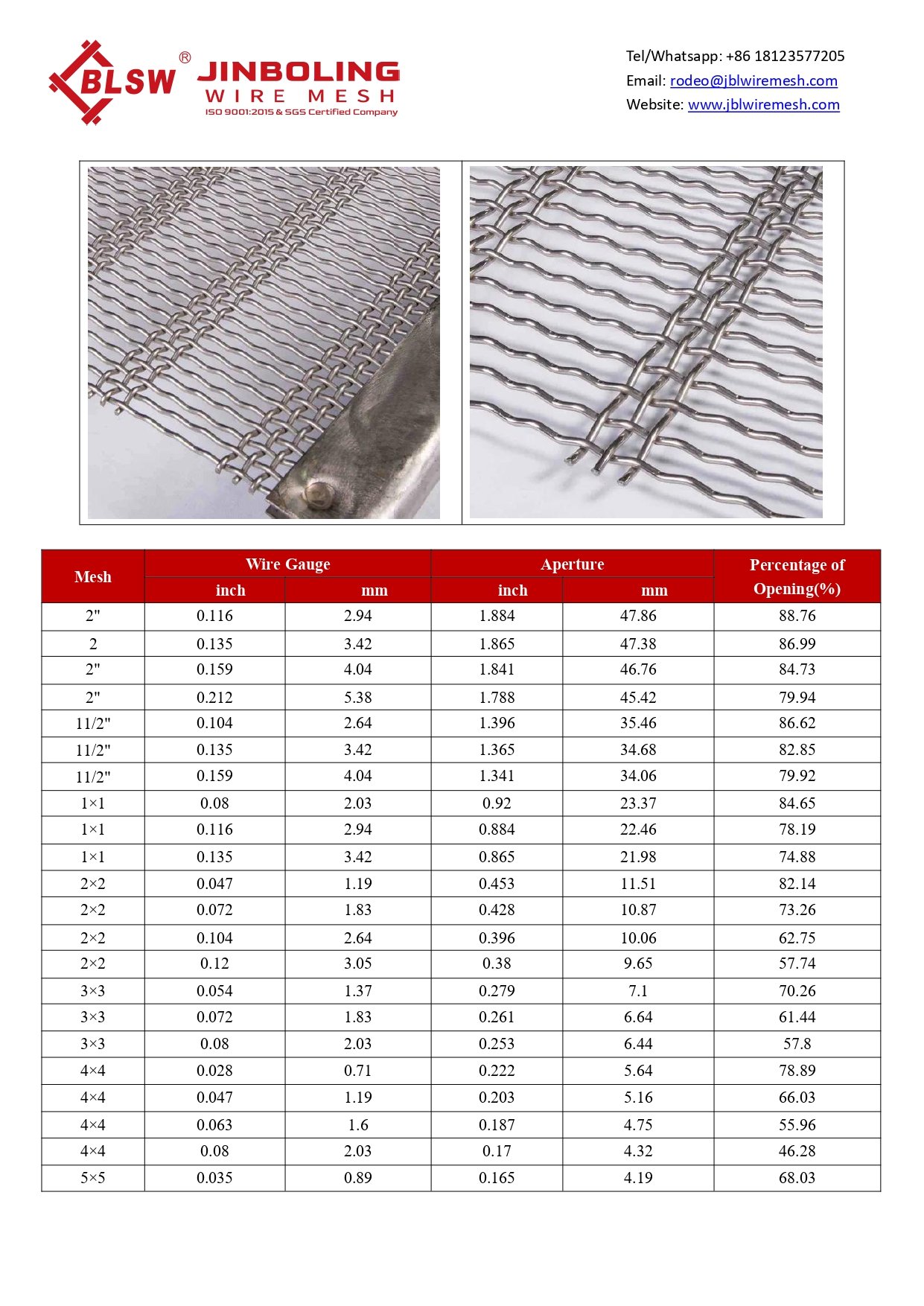

Crimped wire mesh is woven using pre-crimped wires, ensuring accurate spacing and stable structure. It is ideal for heavy-duty applications such as vibrating screens, quarry sieves, grills, and protective fencing in mining, construction, and industrial sectors.

Key Features:

High Strength & Rigidity – Excellent load-bearing capacity for heavy-duty applications

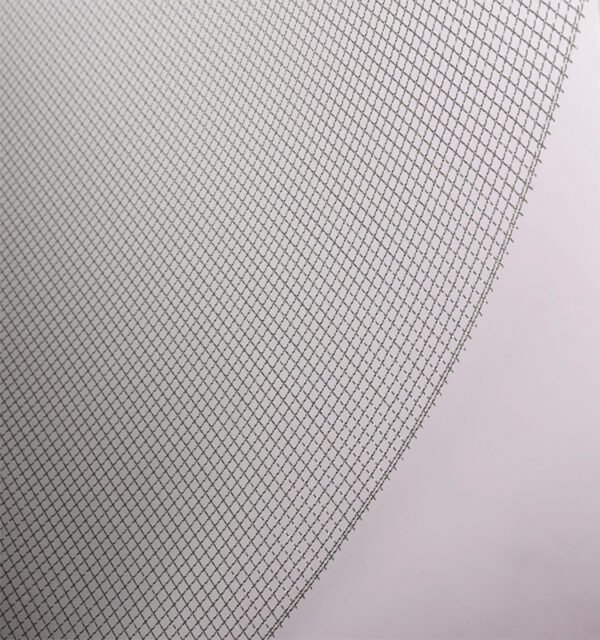

Uniform Openings – Ensures precise screening and filtration performance

Corrosion & Heat Resistance – Suitable for harsh environments and extreme temperatures

Customizable Sizes & Patterns – Available in various crimp styles and specifications

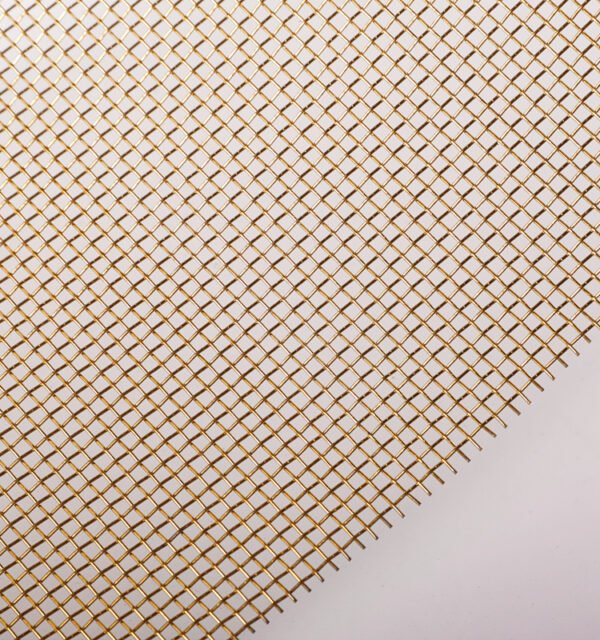

Aesthetic Appeal – Enhances architectural and decorative applications

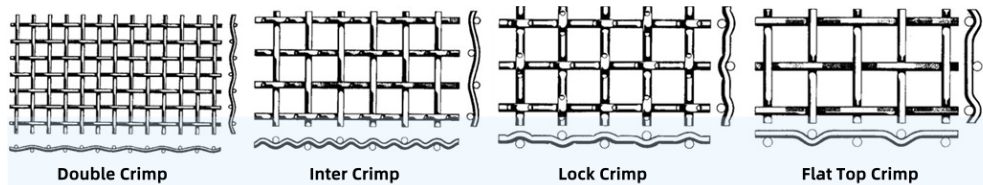

Double Crimped – Pre-crimped warp and weft wires ensure uniform mesh openings, improving stability and strength.

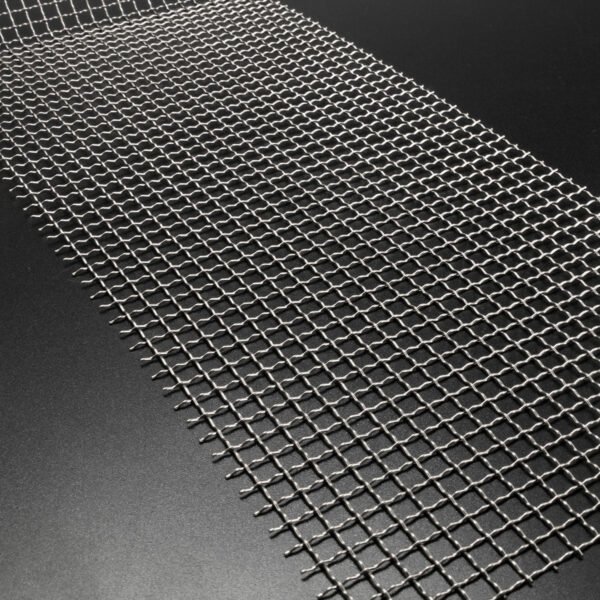

Intermediate Crimped – Features continuous multi-crimps for increased panel rigidity and durability.

Lock Crimped – Offers enhanced screen stability and strength, ideal for heavy-duty sieving, screening, and architectural cladding.

Flat Top Crimped – One side is smooth to reduce friction, commonly used in quarry screens, mining, and architectural applications.

Custom Decorative Crimping – Tailored crimped mesh designs based on customer drawings or samples for artistic and functional applications.

Applications:

- Industrial Uses: Mining, petroleum, chemical processing, and construction

- Filtration & Screening: Graded solid screening, liquid filtration, and mud separation

- Decorative & Structural: Architectural facades, building cladding, and safety barriers

- Household & Commercial: Barbecue grills, vibration screens, and industrial crafts